Introduction to Smart Wells and IoT in Offshore Drilling

Smart wells, equipped with IoT devices, represent a significant innovation in oil extraction. These advanced wells incorporate sensors, actuators, and communication systems, allowing operators to monitor, control, and optimize drilling processes remotely. In offshore drilling—often performed in remote, high-risk environments—smart wells provide enhanced data access and the ability to make adjustments on the go. By enabling Enhanced Oil Recovery (EOR), smart wells improve both operational efficiency and safety while reducing downtime and waste.

According to research by McKinsey & Company, IoT in the oil and gas sector could create up to $1 trillion in value by 2025, with smart wells as a primary driver of this transformation. By improving productivity and safety, reducing downtime, and minimizing environmental impacts, IoT is positioned to make offshore drilling more sustainable and efficient.

How IoT Technology Enables Smart Wells

At the core of smart well functionality is IoT technology. IoT connects a network of devices that collect and transmit data in real-time, enabling offshore control centers to make informed decisions.

The IoT Process in Smart Wells:

- Data Collection: IoT sensors monitor well parameters, such as pressure, temperature, and flow rates.

- Data Transmission: Secure data channels, including satellite, fiber optics, and dedicated wireless networks, transmit this data.

- Analysis and Interpretation: AI-driven analytics process the data, generating insights and predictions for potential issues.

- Decision-Making: Operators receive actionable insights to optimize drilling operations and improve safety.

By reducing manual interventions, IoT technology enhances production, minimizes risk, and cuts down operational costs. Real-time data analysis enables predictive maintenance, reducing the likelihood of equipment failures and avoiding costly unplanned shutdowns.

Key Benefits of IoT-Enabled Smart Wells

The introduction of IoT-enabled smart wells has brought numerous advantages to offshore drilling operations, transforming the industry in multiple ways.

1. Increased Production Efficiency

IoT-enabled smart wells facilitate continuous data collection from every stage of the drilling process, allowing operators to make data-driven decisions in real time. This capability enables companies to optimize extraction techniques and improve production rates significantly.

2. Reduced Downtime and Maintenance Costs

Through predictive maintenance, IoT technology detects and identifies potential issues before they escalate into full-blown problems. Early detection means less downtime for repairs, which translates into substantial cost savings and uninterrupted production.

3. Enhanced Safety

Safety is paramount in offshore drilling. By enabling real-time monitoring, IoT sensors alert operators to potential hazards. This proactive approach allows companies to address threats, such as pressure imbalances or gas leaks, before they lead to accidents, making operations safer for personnel and the environment.

4. Resource Optimization

IoT-enabled smart wells provide the tools needed to manage resources more effectively. By using data insights, companies can minimize wastage, ensuring that resources are utilized efficiently throughout the drilling process.

5. Environmental Impact

With greater control over extraction rates and drilling activities, IoT technology helps reduce emissions, making offshore drilling operations more environmentally friendly. By monitoring flaring and emissions data, operators can take corrective actions to limit environmental impact.

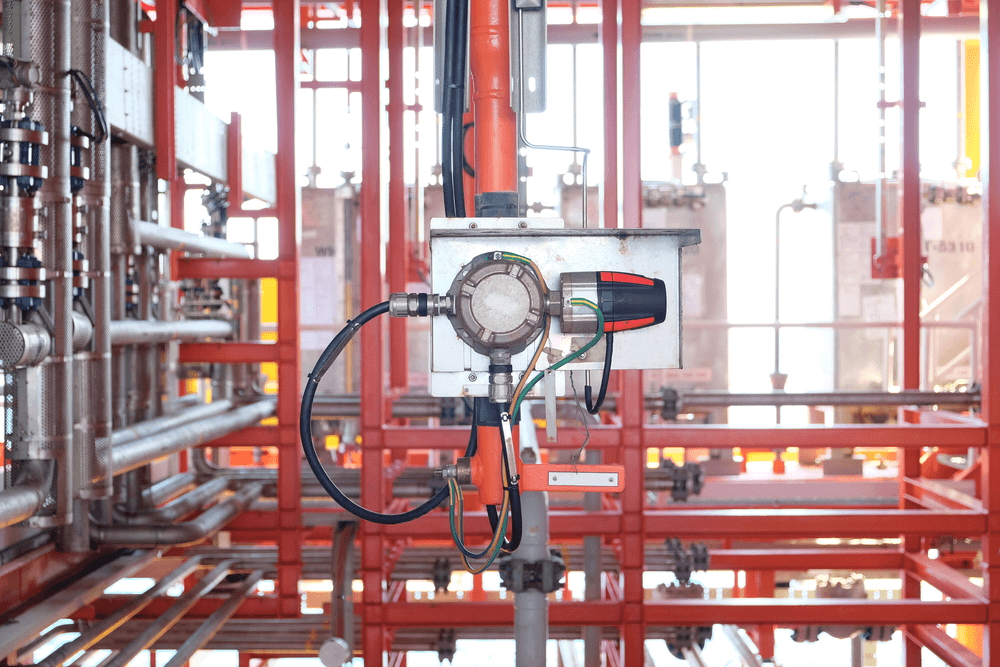

Types of Sensors Used in IoT-Enabled Smart Wells

Smart wells are equipped with a variety of IoT sensors, each serving a specific function to maximize data accuracy and utility. Here’s a look at some of the key sensors used in these high-tech wells:

- Pressure Sensors: These sensors monitor pressure levels within the well, helping prevent dangerous blowouts.

- Flow Sensors: Flow sensors track the volume of oil and gas flowing through the well. This data is essential for optimizing production rates and maximizing output.

- Temperature Sensors: Temperature sensors measure variations in temperature, ensuring safe drilling conditions and extending equipment lifespan.

- Seismic Sensors: These sensors detect underground geological formations, helping operators avoid drilling in potentially hazardous zones. According to Wood Mackenzie, effective seismic sensor use can reduce exploratory costs by 20-25%.

Cost Implications and ROI of Implementing IoT in Smart Wells

The deployment of IoT in offshore drilling requires a substantial initial investment, but the long-term savings and ROI make it a sound investment. Here’s a breakdown of the costs involved and the potential return on investment:

Cost Components:

- Installation: Initial setup of sensors, communication systems, and data processing infrastructure.

- Operational and Maintenance: While IoT reduces manual labor costs, these systems require regular maintenance and occasional upgrades.

- Data Management: Large volumes of data generated by IoT sensors must be stored and analyzed, which involves cloud and storage expenses.

ExxonMobil reported an 8% reduction in production costs and a 10% increase in well productivity due to IoT technology.

Challenges in Implementing IoT for Offshore Drilling

While IoT-enabled smart wells offer numerous benefits, the implementation process is not without challenges. Here are some hurdles companies may face:

- High Technical Demands: Offshore environments are challenging for electronics, exposing equipment to extreme pressures, temperatures, and corrosive saltwater.

- Data Security Risks: IoT networks are vulnerable to cyber threats, risking operational integrity. Security is critical, as 75% of oil and gas companies cite cybersecurity as a primary concern (Deloitte).

- Regulatory Compliance: Companies must adhere to environmental and safety regulations, which adds complexity and cost to IoT deployment.

Environmental Impact of IoT-Enabled Smart Wells

IoT technology plays a significant role in supporting sustainable resource use in the oil and gas industry. By enabling precise control over drilling activities, IoT helps prevent over-extraction and reduces the environmental footprint. BP’s 2022 sustainability report noted that using IoT in smart wells reduced flaring emissions by 25%.

Future Trends: What’s Next for IoT in Offshore Drilling?

As IoT technology advances, the potential for innovation in offshore drilling grows. Here are some emerging trends in IoT-enabled smart wells:

1. Digital Twins

Digital twin technology creates a virtual replica of the well, allowing operators to simulate different scenarios and optimize production without making physical changes. According to Gartner, digital twins could reduce drilling costs by up to 20%.

2. Edge Computing

With edge computing, data is processed locally, reducing latency and enabling faster decision-making.

3. Robotics and Drones

Autonomous devices, including drones and underwater robots, are becoming more common for offshore tasks such as pipeline inspection and maintenance.

Conclusion

The adoption of IoT-enabled smart wells marks a significant transformation in the offshore drilling industry. Through real-time monitoring, predictive maintenance, and data-driven decision-making, smart wells enhance production efficiency, safety, and environmental sustainability. Although implementing IoT in offshore drilling comes with upfront costs, the ROI from increased productivity and reduced downtime makes it a valuable investment.

With future advancements like digital twins, edge computing, and robotics, smart wells will continue to play a pivotal role in improving offshore oil recovery. As companies strive to meet sustainability goals, IoT-enabled smart wells are essential for achieving both operational success and environmental responsibility in offshore drilling.

Ready to Transform Your Offshore Drilling Operations with IoT? Partner with Rejig Digital

At Rejig Digital, we specialize in providing cutting-edge IoT solutions tailored for the oil and gas industry. With our expertise, we help you unlock the full potential of IoT-enabled smart wells to enhance productivity, ensure safety, and achieve sustainable drilling practices.

Whether you’re looking to optimize data collection, implement predictive maintenance, or improve real-time monitoring, Rejig Digital has the tools and experience to take your offshore operations to the next level.

Contact us today to learn how we can help you achieve better results with IoT solutions designed for the future of offshore drilling!