The oil and gas industry is undergoing a major digital shift as organizations face increasing pressure to operate safely, efficiently, and sustainably. Traditional practices, largely dependent on manual inspections, scheduled maintenance, and limited visibility, are being replaced by intelligent, data-driven operations.

This evolution has opened the door to Smart Oilfields and Pipelines, where IoT-based monitoring systems provide real-time insights, automate workflows, and improve decision-making across the entire value chain.

The Shift Toward Smart Oilfields

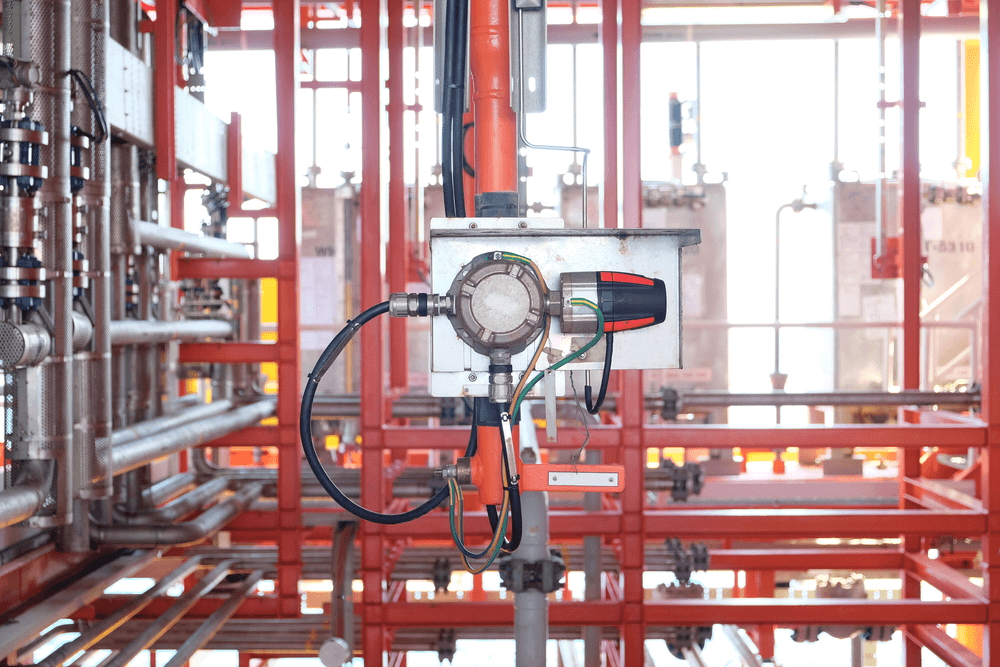

A smart oilfield integrates IoT sensors, cloud platforms, analytics, automation, and remote control systems to build a connected ecosystem. Every asset, from drilling rigs and pumps to storage tanks and refining units, continuously communicates performance data, enabling operators to detect issues early and streamline operations.

By capturing real-time information on pressure, temperature, flow rate, equipment vibration, and environmental conditions, oilfield operators gain a comprehensive understanding of asset behavior. This continuous visibility improves production output, minimizes downtime, and reduces human exposure to high-risk activities.

Key Components of a Smart Oilfield

- IoT Sensors: Monitor equipment health, detect anomalies, and track fluid movement across upstream and midstream operations.

- Edge Devices: Process data at remote sites to support fast response and reduce dependency on cloud connectivity.

- Cloud Platforms: Aggregate large datasets for enterprise-wide analytics, reporting, and historical insights.

- AI & Predictive Analytics: Anticipate equipment failures and optimize maintenance strategies.

- Remote Operations Centers: Enable centralized control and safer, more informed decision-making.

Transforming Pipeline Management with IoT Monitoring

Pipelines remain one of the most critical and vulnerable components of oil and gas infrastructure. Due to their extensive geographic coverage, detecting leaks, pressure changes, or structural issues in real time has historically been challenging.

IoT-enabled pipeline monitoring addresses these gaps by providing continuous surveillance, predictive intelligence, and faster incident response.

Sensors embedded along pipeline networks track flow rate, vibration, soil movement, temperature variations, and pressure levels. AI-driven analytics interpret this data to instantly detect irregular patterns.

Benefits of IoT-Based Pipeline Monitoring

- Early Leak Detection: Identifies micro-leaks, pressure drops, and anomalies before they escalate into major spills.

- Corrosion and Fatigue Tracking: Monitors structural health to prevent failures caused by rust, erosion, and stress.

- Flow Optimization: Automatically adjusts pumping parameters to minimize energy consumption.

- Environmental Protection: Rapid alerting reduces the risk of contamination and ensures compliance with environmental regulations.

- Operational Transparency: Unified dashboards give teams a real-time overview of pipeline performance from any location.

Enhancing Safety Across Oil and Gas Operations

Safety remains a paramount concern across drilling sites, processing plants, and pipeline corridors. IoT solutions create an additional protective layer by continuously monitoring workplace conditions and detecting hazards in advance.

How IoT Improves Safety

- Gas Leak Detection: Sensors detect hazardous gases such as methane and H₂S and trigger instant alerts.

- Worker Safety Monitoring: Wearable IoT devices track worker location, exposure levels, and emergency conditions.

- Equipment Health Insights: Predictive monitoring prevents failures that could endanger personnel or disrupt operations.

- Automated Emergency Response: AI-integrated systems initiate shutdowns and safety protocols during critical events.

These capabilities significantly reduce incident rates while helping organizations comply with stringent global safety standards.

Driving Efficiency with Predictive and Preventive Maintenance

Predictive maintenance is one of the most impactful outcomes of IoT adoption in oilfields. Instead of servicing equipment based on fixed intervals, operators can now forecast failures and perform maintenance only when necessary.

Sensors installed on compressors, valves, motors, and pumps track performance indicators such as vibration signatures, pressure deviations, and temperature fluctuations. When anomalies are detected, the system sends alerts immediately. Advanced algorithms can estimate the asset’s Remaining Useful Life (RUL), enabling precise scheduling and resource planning.

This approach extends equipment lifespan, eliminates unplanned downtime, and reduces maintenance expenditure.

Energy Efficiency and Sustainability Through IoT

Sustainability is becoming a foundational pillar for oil and gas companies. IoT monitoring plays a crucial role by optimizing resource usage, lowering emissions, and improving environmental compliance.

Sustainability Advantages of IoT

- Optimized Energy Consumption: Smart motors and pumps operate at the most efficient settings.

- Emission Tracking: Sensors measure CO₂, methane, and NOx levels to support ESG reporting.

- Reduced Water Waste: Intelligent flow control improves water usage during drilling and processing.

- Data-Driven ESG Decisions: Analytics platforms help leaders align operations with global sustainability benchmarks.

With IoT, companies can maintain profitability while pursuing environmentally responsible operations.

Integration with Advanced Technologies

IoT delivers greater value when paired with advanced technologies like AI, Machine Learning, and Digital Twins.

- AI & ML: Analyze complex datasets, identify hidden patterns, and continuously improve operational models.

- Digital Twins: Virtual simulations of wells, pipelines, and process units help operators predict outcomes, plan maintenance, and test scenarios.

- 5G & Edge Computing: Enhance connectivity and accelerate data processing in remote locations.

Together, these technologies enable highly automated, intelligent, and autonomous operations.

The Road Ahead: Building the Future of Smart Oil and Gas

IoT adoption in oilfields and pipelines is no longer optional. It’s essential for maintaining competitive advantages. As global energy demand grows and environmental expectations intensify, connected systems will be central to operational success.

Organizations like Rejig Digital are empowering the industry with advanced Industrial IoT (IIoT) platforms designed to connect field assets, automate workflows, and deliver real-time insights. These platforms offer complete visibility across exploration, production, and distribution, ensuring every stage operates at peak efficiency.

Conclusion

Smart oilfields and IoT-driven pipelines represent the next major leap in digital transformation for the energy sector. With capabilities ranging from predictive maintenance and automated leak detection to energy efficiency and ESG reporting, IoT monitoring delivers measurable value at every level of operation.

As the industry moves toward intelligent, connected infrastructure, IoT will continue to be the foundation enabling safer, greener, and more efficient oil and gas ecosystems.

📈 Take the next step toward safer, smarter, and more sustainable oilfield operations.

Book a consultation with Rejig Digital and explore how our IoT-based solutions can help you detect leaks early, minimize downtime, and stay fully compliant.