Introduction: The CFO’s Role in IIoT Adoption

Industrial IoT (IIoT) is no longer a futuristic concept — it is a proven driver of operational efficiency, predictive intelligence, and cost optimization in manufacturing. However, for many CFOs and decision-makers, the critical question remains: how can IIoT deliver measurable financial returns, not just operational improvements?

At Rejig Digital, we have worked with leading manufacturers to implement IIoT-driven strategies that directly improve CapEx (capital expenditure) and OpEx (operational expenditure) outcomes. With long-term financial benefits spanning reduced downtime, enhanced productivity, energy savings, and improved quality control, our expertise helps CFOs turn IIoT into a financial growth lever — not just a technology experiment.

This blog provides a strategic CFO’s guide to measure, track, and maximize ROI from IIoT in manufacturing environments.

Read More:

-

Step-by-Step Guide to Implementing IIoT in Your Manufacturing Plant — Dive deeper into hands-on IIoT implementation with Rejig Digital’s Arete platform.

Understanding ROI in IIoT: Beyond Simple Payback

Before diving into financial strategies, CFOs must understand how IIoT ROI differs from conventional technology investments.

1. Direct ROI Metrics

- Downtime Reduction: Quantify cost savings by measuring reduced machine failures and unplanned outages.

- Maintenance Cost Optimization: Track how predictive maintenance lowers labor and spare part expenses.

- Energy Savings: Calculate reduced utility costs from smart energy monitoring.

2. Indirect ROI Metrics

- Improved Quality and Yield: Fewer defects translate to fewer recalls and less waste.

- Faster Time-to-Market: Smart automation shortens production cycles, increasing revenue potential.

- Compliance and Risk Mitigation: Avoidance of penalties and costly non-compliance issues.

3. Strategic ROI Metrics

- Scalability of Operations: Ability to integrate future automation and digital twins.

- Competitive Advantage: Market differentiation through cost-efficient, data-driven operations.

Step 1: Establish Clear Financial Objectives

IIoT investments must begin with a business-driven financial roadmap rather than a technology-first approach. CFOs should define:

- Baseline Metrics: Current cost of downtime, energy, labor, and scrap rates.

- Target Outcomes: Percentage reduction in downtime, expected energy savings, or improved OEE (Overall Equipment Effectiveness).

- Financial KPIs: ROI percentage, Net Present Value (NPV), Internal Rate of Return (IRR), and Payback Period.

For example, if downtime costs a plant $10,000 per hour and IIoT predictive maintenance reduces downtime by 20%, that is a direct annual savings of millions depending on machine utilization.

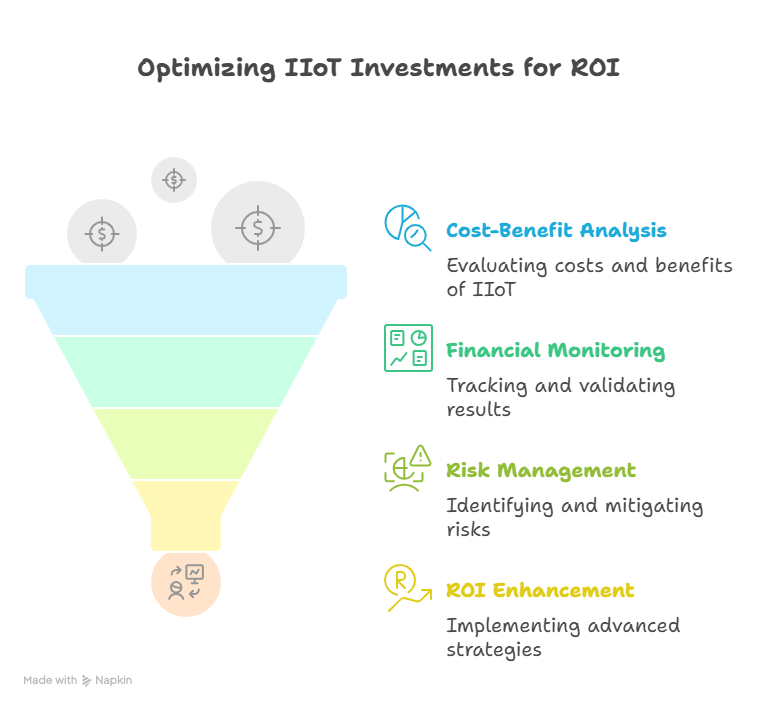

Step 2: Create a Cost-Benefit Model for IIoT

CFOs must adopt a structured Total Cost of Ownership (TCO) and Value Model to evaluate IIoT investments.

Key Cost Components

- Hardware: Sensors, gateways, and controllers.

- Software and Platforms: IIoT platforms, data analytics tools, cloud integration.

- Connectivity: 5G, Wi-Fi, or private LTE.

- Implementation and Integration: Professional services for deployment.

- Change Management: Training staff and reskilling programs.

Key Benefit Streams

- Operational Efficiency Gains (higher throughput, reduced cycle time).

- Resource Optimization (reduced energy, labor, and raw material wastage).

- Revenue Uplift (faster delivery, new service-based models).

Pro Tip: CFOs should ensure every investment line item has a mapped revenue or cost-saving counterpart for better board-level approval.

Step 3: Build a Financial Monitoring Framework

ROI does not end at deployment. CFOs must continuously track and validate results through a financial monitoring framework.

A Three-Layer Approach:

- Operational KPIs: Machine uptime, energy consumption per unit, defect rates.

- Financial KPIs: Cost per unit, maintenance spend, yield improvement.

- Strategic KPIs: Market share impact, customer retention, sustainability index.

Suggested Tools for CFOs

- Digital Dashboards with IIoT and ERP integration.

- Predictive Analytics Reports to track forecasted vs. actual cost savings.

- Benchmarking Studies across plants or industry peers.

This ensures IIoT is not perceived as a “cost center” but as a profit center enabler.

Step 4: Risk Management and ROI Safeguards

While the potential for ROI is significant, CFOs must account for risks that can erode returns.

Common Risks

- Cybersecurity Breaches: Unsecured IoT endpoints can result in data theft and downtime costs.

- Integration Overheads: Poor compatibility with legacy systems can inflate costs.

- Scaling Challenges: Pilot projects often show strong ROI, but scaling across plants may dilute returns.

Financial Safeguards

- Allocate 5–10% of IIoT budgets to cybersecurity and compliance.

- Build contingency buffers for integration delays.

- Use phased rollouts with measurable milestones to avoid over-investment.

Step 5: Enhancing ROI Through Advanced Strategies

1. Predictive and Prescriptive Maintenance

By leveraging AI/ML algorithms on IIoT data, plants can shift from preventive to predictive maintenance, saving up to 30–40% of maintenance costs.

2. Energy Optimization with IIoT

Integrating IIoT with energy management systems can reduce consumption by 10–15% annually, directly boosting operating margins.

3. Digital Twin Investments

CFOs should consider Digital Twin technology, which enables simulation of plant performance for process optimization and risk reduction — cutting down trial-and-error costs.

4. New Revenue Models

IIoT can enable manufacturers to move towards “as-a-service” business models, offering remote monitoring, performance-based guarantees, and service subscriptions.

5. Sustainability as ROI

With ESG compliance gaining momentum, IIoT-driven energy efficiency and waste reduction directly contribute to long-term sustainable ROI and investor confidence.

Step 6: Communicating ROI to the Board and Stakeholders

For IIoT adoption to gain momentum, CFOs must effectively present ROI to boards, investors, and stakeholders.

Communication Checklist

- Clear Financial KPIs: ROI%, NPV, IRR, and payback timelines.

- Case Studies & Benchmarks: Industry examples of realized savings.

- Scalability Plans: How initial savings will compound at scale.

- Risk Mitigation Plans: Assurance on cybersecurity, compliance, and data governance.

By framing IIoT as a strategic enabler of cost optimization and revenue growth, CFOs ensure stronger buy-in.

Read More:

-

IIoT Systems Management: Unlocking the Power of Smart Manufacturing — Learn how to transform raw data into insights and smart operations.

Real-World Example of ROI in Action

A global automotive parts manufacturer deployed IIoT-enabled predictive maintenance across three plants. The result:

- 20% reduction in downtime, saving nearly $15M annually.

- 15% decrease in energy costs, aligned with sustainability goals.

- 5% improvement in yield, translating into faster market delivery.

The company achieved payback in under 18 months while strengthening its ESG commitments, making IIoT a financial and strategic win.

Read More:

-

Top 15 Industrial IoT Sensors Driving Efficiency — Discover which sensors can deliver quick wins in maintenance, safety, and energy.

Conclusion: Turning IIoT into a Profit Center

For CFOs and decision-makers in manufacturing, IIoT is no longer just a technology investment — it is a financial strategy. By setting clear financial objectives, creating cost-benefit models, establishing monitoring frameworks, mitigating risks, and leveraging advanced IIoT strategies, CFOs can maximize returns while future-proofing operations.

IIoT adoption is not about “if,” but about “how fast and how effectively” it can be scaled. The manufacturers who act decisively today will be the ones capturing higher market share, stronger investor trust, and superior profit margins tomorrow.