In today’s competitive oil and gas industry, technology plays a crucial role in improving operational efficiency, reducing costs, and enhancing safety. One of the most significant innovations is the adoption of IoT acoustic sensors, which are transforming oil field operations by enabling real-time monitoring, oil composition analysis, and cost optimization.

This article explores how IoT acoustic sensors are revolutionizing oil field operations and the key benefits they bring to the oil and gas sector.

What Are IoT Acoustic Sensors?

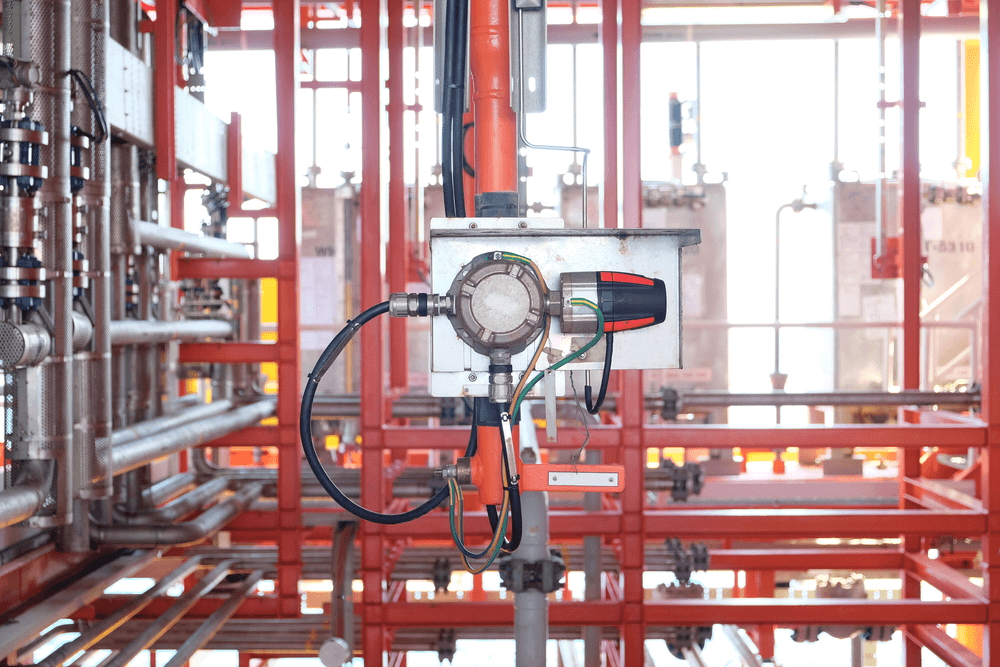

IoT acoustic sensors use sound waves to measure and analyze the properties of fluids moving through pipelines, reservoirs, or wellheads. These sensors operate by emitting sound waves through the fluid, measuring the time it takes for the waves to return, and calculating various properties such as flow rate, density, and viscosity.

Key Features of IoT Acoustic Sensors:

- Real-time Data Collection: Provides continuous monitoring and analysis.

- Wireless Connectivity: IoT-enabled sensors transmit data directly to cloud-based platforms for immediate access and action.

- High Precision: Measures fluid properties with high accuracy, offering insights that traditional methods can’t match.

These sensors are part of the broader IoT ecosystem, connecting various devices to enable intelligent, data-driven decision-making. Now, let’s explore how these sensors are improving critical aspects of oil field operations.

1. Enhancing Flow Rate Monitoring

Flow rate monitoring is crucial in oil field operations as it helps operators maintain optimal extraction rates, prevent downtime, and avoid pipeline damage. Traditional flow rate sensors, such as pressure-based devices, often lack the precision needed for accurate monitoring over long periods.

How IoT Acoustic Sensors Improve Flow Rate Monitoring:

- Real-time Monitoring: IoT sensors provide instant flow rate data, allowing for immediate detection of anomalies.

- Improved Accuracy: Unlike traditional pressure sensors, acoustic sensors can measure flow rates with greater accuracy, even in challenging environments like offshore drilling rigs or deep-water wells.

- Early Detection of Issues: By continuously monitoring flow, IoT acoustic sensors can detect potential blockages, leaks, or irregularities before they escalate, reducing the risk of pipeline failures and minimizing maintenance costs.

Benefits:

- Faster Decision Making: Real-time data enables operators to make quick adjustments to optimize production.

- Increased Operational Efficiency: Continuous flow rate monitoring reduces manual checks and minimizes the chances of missed issues.

2. Advancing Oil Composition Analysis

In the oil and gas industry, oil composition is a critical factor that influences production processes, quality control, and product pricing. Traditional methods of analyzing oil composition, such as laboratory tests, are time-consuming and expensive.

How IoT Acoustic Sensors Enhance Oil Composition Analysis:

- On-Site, Real-Time Analysis: IoT sensors measure fluid properties like viscosity, density, and gas-to-liquid ratios directly at the wellhead or pipeline, providing instant insights into oil quality.

- Faster Processing: Unlike conventional methods, which require samples to be sent to a lab, acoustic sensors offer immediate feedback without interrupting operations.

- Non-invasive: These sensors analyze the composition of oil without disrupting production, helping operators make adjustments without downtime.

Benefits:

- Cost Savings: Reduces the need for manual sampling and external lab tests, cutting operational costs.

- Improved Oil Quality Control: Real-time data helps maintain consistent oil quality, ensuring that product specifications are met.

- Enhanced Recovery Rates: Continuous monitoring of oil properties allows for better extraction and transportation strategies, increasing recovery efficiency.

3. Improving Cost Efficiency and Reducing Operational Costs

The oil and gas industry faces constant pressure to improve cost efficiency while maximizing output. IoT acoustic sensors are instrumental in reducing operational costs through predictive maintenance, real-time monitoring, and improved decision-making.

How IoT Acoustic Sensors Drive Cost Efficiency:

- Predictive Maintenance: By detecting issues such as leaks, blockages, or irregular flow early, these sensors allow for proactive maintenance, reducing the need for costly repairs and downtime.

- Optimized Production: With accurate, real-time data, operators can fine-tune extraction processes, reducing waste and improving yield.

- Labor Savings: By automating many manual processes (e.g., oil sampling, flow measurement), IoT sensors help reduce labor costs and human error.

Key Cost Benefits:

- Savings of 20-30%: Many companies report up to 30% savings in operational costs after implementing IoT sensors.

- Reduced Downtime: Early problem detection prevents major system failures, keeping operations running smoothly.

- Increased Production Efficiency: Optimized extraction processes help improve oil recovery, boosting profitability.

Conclusion: The Future of Oil Field Operations

The adoption of IoT acoustic sensors is reshaping the future of oil field operations. These sensors are revolutionizing the way operators monitor flow rates, analyze oil composition, and optimize cost efficiency. As the oil industry continues to embrace technological advancements, IoT acoustic sensors will remain a crucial tool for improving productivity and sustainability.

By providing real-time insights and enabling smarter decision-making, these sensors empower operators to enhance operational efficiency, minimize risks, and reduce costs. As the technology continues to evolve, the possibilities for IoT in the oil and gas sector are endless.

Ready to enhance your oil field operations with IoT acoustic sensors? Contact Rejig Digital to learn how our advanced IoT solutions can improve your flow rate monitoring, oil composition analysis, and cost efficiency. Get in touch today to start transforming your operations!