A digital twin is a continuously synchronized virtual representation of a physical asset, system, or process, created using real-time data, historical performance metrics, and analytical models. Rather than serving as a visualization tool alone, it provides operational intelligence, allowing organizations to monitor performance, simulate changes, predict failures, and optimize outcomes across the asset lifecycle.

In practical terms, a digital twin mirrors how a physical asset behaves in real operating conditions. Unlike static simulations or standalone 3D models, it maintains a live, bidirectional connection with its physical counterpart through Industrial Internet of Things (IIoT) infrastructure. This connection enables enterprises to understand current performance and anticipate how assets will behave under future scenarios before disruptions occur.

As a foundational capability of Industry 4.0, digital twin technology supports smarter manufacturing, resilient supply chains, predictive maintenance, and large-scale digital transformation initiatives, helping organizations move from reactive operations to data-driven decision-making.

Why Digital Twins Matter in Modern Industrial Environments

Modern industrial environments demand real-time visibility, operational efficiency, and predictive decision-making across complex assets and systems. Digital twin technology enables this by creating a continuously synchronized virtual representation of physical assets using Industrial Internet of Things (IIoT) data, analytics, and intelligent models. This real-time connection allows organizations to monitor asset performance, understand system behavior, and gain actionable insights across the entire asset lifecycle.

By combining live sensor data with historical and contextual information, a digital twin shifts industrial operations from reactive monitoring to predictive maintenance and proactive optimization. Organizations can simulate operational changes, anticipate failures, reduce unplanned downtime, and improve asset performance without disrupting live operations. As a key enabler of Industry 4.0 and digital transformation, digital twins provide the intelligence required to build scalable, resilient, and data-driven industrial systems.

The Role of IIoT in Digital Twin Architecture

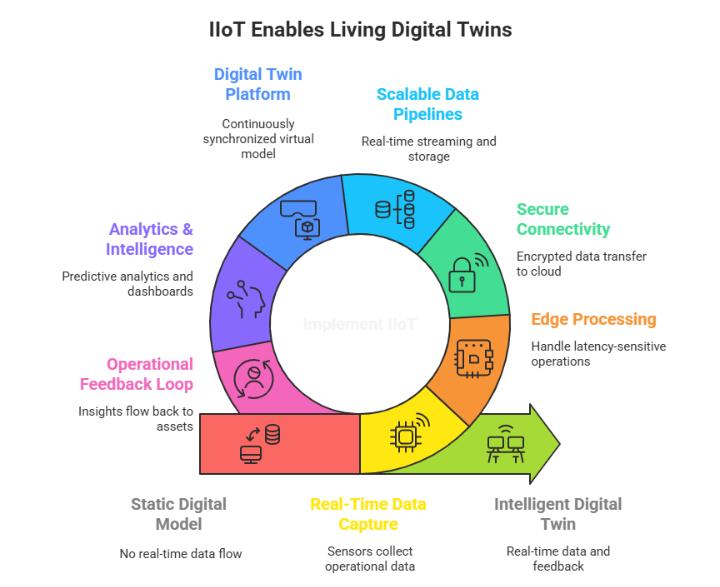

A digital twin is only as powerful as the data that feeds it. Industrial Internet of Things (IIoT) serves as the nervous system of digital twin architecture by enabling continuous, real-time data acquisition from physical assets and operational environments.

IIoT enables digital twins through:

- Sensor-based data capture including temperature, vibration, pressure, energy consumption, flow, and motion

- Edge processing for latency-sensitive and mission-critical operations

- Secure connectivity between physical assets, cloud platforms, and analytics layers

- Scalable data pipelines supporting real-time monitoring and historical analysis

Without IIoT, a digital twin remains a static representation. With IIoT, it becomes a living, continuously evolving operational system capable of real-time insight and optimization.

How Digital Twin Technology Works in Practice

While digital twin implementations vary across industries, most systems follow a structured lifecycle that connects physical assets with intelligent, data-driven virtual models.

1. Data Acquisition

Physical assets are equipped with IIoT sensors and connected systems that continuously collect real-time and historical operational data, including temperature, vibration, pressure, energy consumption, and machine status.

2. Virtual Modeling

A digital twin model is created to represent the asset’s structure, behavior, operational logic, and constraints. This virtual representation accurately reflects how the physical system operates under real-world conditions.

3. Continuous Synchronization

Live data streams from IIoT devices keep the digital twin continuously aligned with the current state of the physical asset, ensuring accurate monitoring and real-time visibility.

4. Analytics and Simulation

Using advanced analytics, artificial intelligence (AI), and machine learning, the digital twin identifies anomalies, predicts potential failures, and runs “what-if” simulations to evaluate different operational scenarios.

5. Feedback and Optimization

Insights generated by the digital twin enable data-driven decisions and automation, such as predictive maintenance scheduling, process optimization, and system reconfiguration.

Digital Twin vs Simulation vs 3D Models

Digital twin technology is often misunderstood as an advanced simulation or visualization tool, but the differences are fundamental and strategically important.

- 3D models provide a static visual representation of an asset’s geometry. They show how an object looks, but not how it behaves or performs over time.

- Simulations evaluate predefined scenarios in a controlled virtual environment, typically without continuous connection to real-world systems.

- Digital twins, in contrast, maintain a real-time, bi-directional connection with physical assets, continuously reflecting live operational conditions and influencing real-world decisions.

This continuous feedback loop—powered by IIoT data, analytics, and AI—is what elevates digital twins from engineering tools to enterprise-grade decision intelligence systems.

Types of Digital Twins in Industrial Systems

Industrial environments typically deploy multiple digital twin types to gain layered and scalable operational insight.

Component Twins

Component twins focus on individual parts such as pumps, motors, valves, sensors, and bearings, providing granular visibility into performance and wear patterns.

Asset Twins

Asset twins represent complete machines or functional units composed of multiple components, enabling real-time monitoring of how those components interact as a single system.

System Twins

System or unit twins model interconnected assets operating together within a plant, production line, or facility, helping identify performance bottlenecks and optimization opportunities at a system level.

Process Twins

Process twins deliver end-to-end visibility across production workflows, supply chains, and operational processes, ensuring that the entire ecosystem operates efficiently, not just individual assets.

Most mature digital twin implementations combine all four types to deliver comprehensive, enterprise-wide intelligence.

Business Benefits of Digital Twin Technology

Digital twin technology delivers measurable value across operational, financial, and strategic dimensions.

Predictive Maintenance

By detecting deviations from normal operating behavior, digital twins enable early fault detection, reducing unplanned downtime, maintenance costs, and asset failures.

Operational Efficiency

Continuous performance monitoring highlights inefficiencies in energy consumption, throughput, and resource utilization, driving data-backed optimization.

Faster Engineering and Innovation

Virtual validation reduces reliance on physical prototypes, shortens design cycles, and accelerates time to market.

Risk Reduction

Scenario modeling allows organizations to test operational changes safely in a virtual environment before deploying them in live systems.

Scalable Digital Transformation

Digital twins provide a structured foundation for AI-driven automation, advanced analytics, and long-term Industry 4.0 initiatives.

Industry Applications of Digital Twins

Digital twin adoption spans multiple industries where operational complexity and asset criticality are high:

- Manufacturing: Simulate entire production lines, optimize plant layouts, predict equipment failures through predictive maintenance, and test new processes virtually before physical implementation. This reduces waste, minimizes downtime, and accelerates production efficiency.

- Healthcare: Develop patient-specific digital twins to model organs and treatment outcomes, optimize hospital operations, and simulate responses to mass emergencies or critical medical scenarios, ensuring better patient care and resource planning.

- Smart Cities & Infrastructure: Create virtual replicas of urban environments to optimize traffic flow, manage energy and water distribution, simulate climate impacts like floods, and plan infrastructure projects with greater precision and efficiency.

- Energy & Utilities: Monitor complex power grids in real time, predict maintenance needs for turbines and power plants, and optimize energy distribution for cost-efficiency and reliability.

- Automotive: Design and test connected vehicles, simulate performance under various conditions, and provide personalized customer experiences using virtual vehicle models, reducing physical prototyping costs

- Aviation: Simulate flight operations, crew management, and airport ground operations to improve safety, efficiency, and regulatory compliance while optimizing operational workflows.

Across industries, digital twins enable data-driven operational confidence and resilience.

Implementation Challenges and Practical Considerations

While digital twins deliver significant ROI, effective deployment requires addressing key challenges:

- High-Quality Data & Reliable IIoT Connectivity: Accurate sensor data and uninterrupted IIoT networks are essential for real-time insights

- Legacy System Integration: Seamless connection with existing ERP, MES, and industrial control systems ensures smooth adoption

- Model Accuracy, Scalability & Performance: Digital twins must scale with assets and maintain precise real-time representations of complex systems

- Cybersecurity & Access Control: Protecting sensitive operational data with strong security protocols is critical for enterprise adoption

- Cross-Functional Skills: Teams need expertise in IIoT, AI, analytics, and domain-specific engineering to extract maximum value.

Enterprises achieve the best outcomes by starting with clearly defined use cases, adopting modular architectures, and selecting scalable digital twin platforms aligned with long-term transformation goals.

The Future of Digital Twin Technology

Emerging innovations are expanding the capabilities of IIoT-enabled digital twins:

- AI-Driven Autonomous Optimization: Systems self-learn and adjust for maximum operational efficiency

- Digital Twin as a Service (DTaaS): Cloud-based models for scalable, cost-effective deployment

- Enterprise-Wide System-of-Systems Twins: Unified insights across multiple plants and assets

- Human & Workforce Digital Twins: Simulate workforce productivity, skill allocation, and safety planning

- Deeper Integration with Enterprise Systems: Connect with ERP, MES, CMMS, and industrial control systems for holistic operational intelligence.

As adoption grows, digital twins will evolve from decision-support tools to self-optimizing industrial systems, driving smarter, AI-powered operations.

Conclusion

Digital twin technology, integrated with IIoT, AI, and advanced analytics, is no longer a futuristic concept—it’s a game-changer for modern industrial systems. By creating real-time virtual replicas of physical assets, organizations can predict failures before they happen, optimize operations, and drive smarter, faster decisions across manufacturing, energy, automotive, healthcare, and smart city applications.

Enterprises embracing digital twins gain a competitive edge by improving efficiency, reducing costs, accelerating innovation, and achieving scalable Industry 4.0 transformation. From predictive maintenance to operational excellence, digital twins turn complex industrial data into actionable insights, ensuring resilience, agility, and long-term growth.

Don’t let your operations fall behind—invest in digital twin technology today and transform the way your business designs, monitors, and optimizes industrial systems.