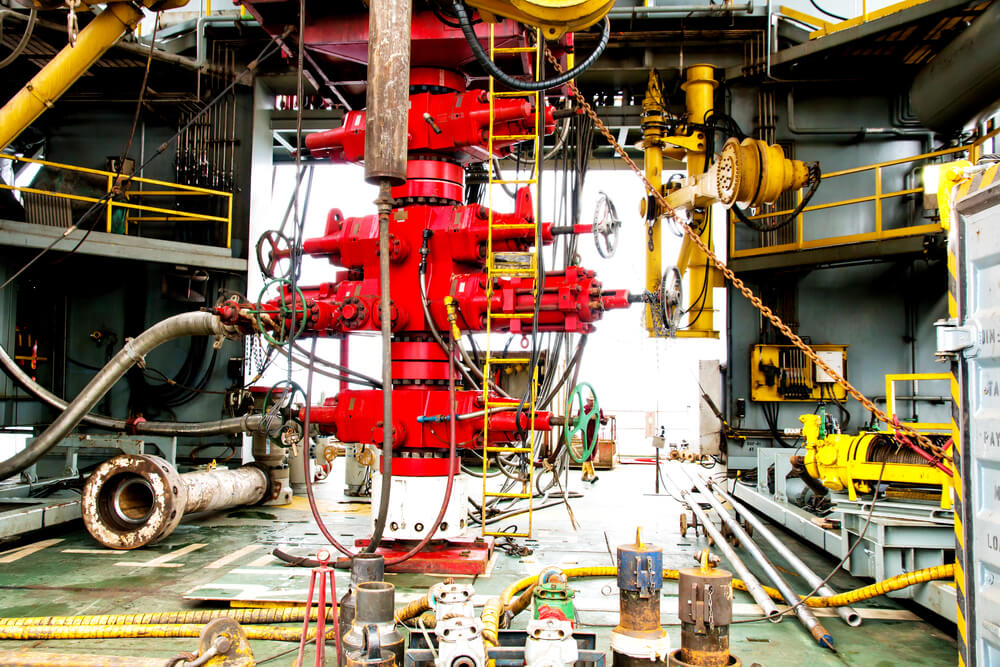

Introduction: Why Blowout Prevention is Critical in Oil & Gas Drilling

Oil and gas drilling is a high-risk operation. Blowouts, which are the uncontrolled release of oil, gas, or fluids, can result in catastrophic damage. These include loss of life, environmental disasters, and massive financial costs. The key to avoiding such disasters? Continuous monitoring. This powerful tool can detect potential issues before they become major problems. Let’s dive into how continuous monitoring helps prevent blowouts and well control issues.

What is Continuous Monitoring?

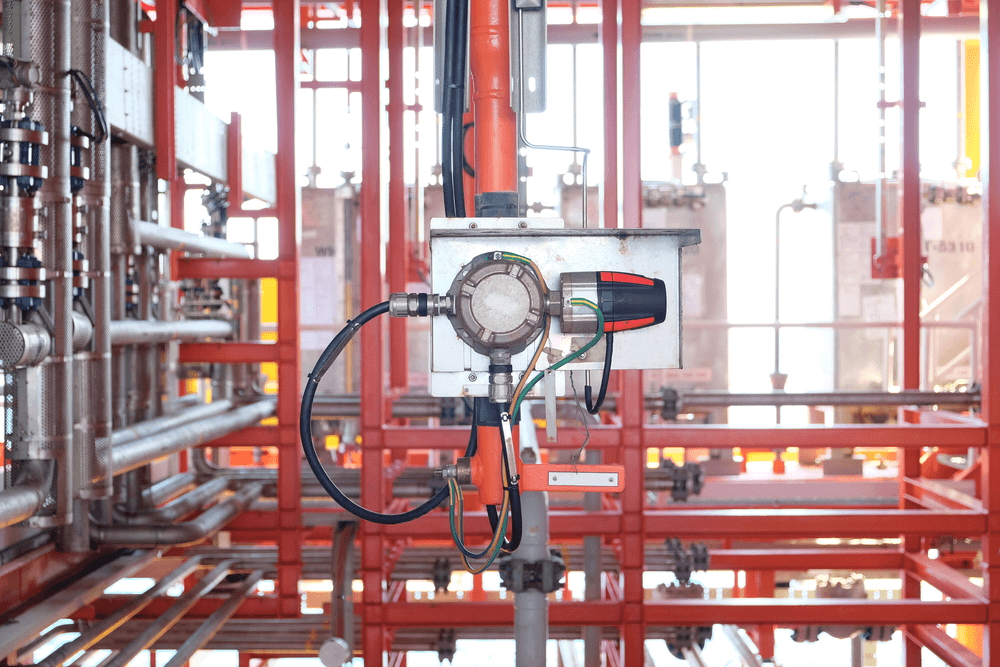

Continuous monitoring involves real-time tracking of well conditions through sensors that measure pressure, temperature, flow rates, and other critical parameters. This data is continuously fed into systems that alert operators of any potential problems. By catching small issues early, operators can act quickly, preventing blowouts and well control problems.

How Continuous Monitoring Helps Prevent Blowouts

- Real-Time Data Collection

Continuous monitoring collects data from sensors that measure well pressure, temperature, and flow rates. By analyzing this data in real-time, operators can spot irregularities that may lead to a blowout. For example, pressure spikes or temperature changes can be caught early, allowing for immediate corrective action.

Key Statistics: Continuous monitoring systems reduce blowouts by up to 80%. (Source: Industry research report, 2023).

- Early Warning System

Small changes in well conditions are often the first signs of a problem. Continuous monitoring acts as an early warning system, alerting operators when pressure, temperature, or flow readings are off. This allows quick intervention to prevent blowouts.

- Preventing Kicks and Pressure Surges

Kicks happen when formation fluids enter the wellbore, causing pressure imbalances. Continuous monitoring detects these pressure changes in real-time, allowing operators to take control before the pressure surge escalates into a blowout.

- Better Well Control

Real-time monitoring helps operators adjust mud weight, pressure, and flow rates to keep the well under control. Proactively managing these variables reduces the risk of uncontrolled releases and blowouts.

Example: A study by DrillingTech (2022) showed that real-time pressure adjustments reduced blowout incidents by 15%.

Benefits of Continuous Monitoring

- Cost Savings: By reducing downtime and preventing costly blowouts, continuous monitoring can save oil and gas companies millions of dollars annually.

- Safety Improvement: The ability to detect and address issues early reduces the chances of accidents, making operations safer for workers and the environment.

- Increased Efficiency: With constant monitoring, operators can optimize operations, making adjustments to improve well performance and reduce costly interruptions.

| System Type | Cost Range | Key Features | Ideal For | Potential Savings & Benefits |

|---|---|---|---|---|

| Basic Systems | $50,000 – $200,000 | – Basic well sensors for pressure, temperature, and flow rate measurement – Real-time data monitoring – Basic data logging and alert system – Limited analytics and reporting capabilities |

– Small to mid-sized drilling operations – Low to moderate risk wells |

– Reduces downtime caused by undetected issues by up to 30% – Decreases the likelihood of blowouts by detecting early-stage problems – Low investment cost relative to return, improving overall cost efficiency in smaller operations. |

| Advanced Systems | $200,000 – $500,000 | – Advanced sensor technology for precise measurement of pressure, temperature, flow, and mud weight – Real-time predictive monitoring and analytics – Integration with advanced well control systems – Data visualization and reporting for more informed decision-making |

– Complex wells with varied formation pressures – Higher-risk areas with tight drilling margins |

– Reduces blowout risk by up to 50% – Improves safety by providing earlier detection of abnormal trends – Optimizes drilling parameters, saving time and preventing costly equipment damage. – Enhances operational efficiency through detailed data analysis and predictive insights. |

| Full-Scale Systems | $500,000 – $1,000,000+ | – Comprehensive sensor suite covering pressure, temperature, flow, mud weight, and other critical parameters – Predictive analytics and real-time alerts for emergency response – Integration with automated control systems for immediate intervention – Advanced software with machine learning capabilities for anomaly detection and trend forecasting |

– Large-scale drilling operations – High-risk wells in offshore or deepwater environments – Operations requiring round-the-clock, high-level monitoring |

– Can save millions of dollars by preventing catastrophic blowouts and reducing costly operational interruptions – Reduces blowout-related damages by ensuring real-time intervention and monitoring – Increases ROI by up to 20% by minimizing expensive delays, maximizing well productivity, and optimizing safety protocols. |

| Additional Features (Applicable to All Systems) | – Cloud-based or remote access to monitoring systems for off-site operation management – Customizable dashboards with key metrics for real-time monitoring – Historical data analysis for better predictive models |

– More accurate forecasts of well life and performance – Enhanced ability to plan for future operations based on historical data trends and predictive analysis |

How Continuous Monitoring Reduces Blowout Risks

A blowout can cost over $100 million in damages, not including the environmental cleanup. By catching issues early, continuous monitoring systems help companies avoid these high costs. The return on investment (ROI) is clear, with many companies reporting savings of up to 20% in overall operational costs.

Frequently Asked Questions (FAQ)

Q1: How does continuous monitoring prevent blowouts?

Continuous monitoring detects small changes in pressure, temperature, or flow rates. These changes often signal a potential blowout, allowing operators to take action before it escalates.

Q2: What types of sensors are used in continuous monitoring?

Sensors for pressure, temperature, flow rate, and mud weight are commonly used. These sensors feed data to real-time systems that allow operators to make timely decisions.

Q3: How much does it cost to implement continuous monitoring?

The cost depends on the system’s complexity. Basic systems start at around $50,000, while more advanced systems can cost up to $1 million for full-scale monitoring.

Q4: What training is required for operators?

Operators must undergo well control training and learn how to interpret data from continuous monitoring systems. Regular drills and training are crucial to ensuring preparedness for emergency situations.

Conclusion: The Value of Continuous Monitoring in Oil & Gas Drilling

Blowouts and well control issues can lead to catastrophic results. But with continuous monitoring, operators can act before things go wrong. It improves safety, reduces costs, and ensures better well control. If you’re looking to improve your well’s safety and efficiency, implementing continuous monitoring is a smart choice for any oil and gas operation.