The era of Industry 4.0 is here, and it’s transforming manufacturing like never before. At the heart of this transformation is the Industrial Internet of Things (IIoT), which promises to revolutionize operations, increase efficiency, and unlock new levels of productivity across the entire supply chain. However, while manufacturers are quickly embracing IIoT, many are still grappling with how to harness its full potential.

IIoT Systems Management: The Missing Link in Factory Digitization

In many factories, the focus has been on collecting data and digitizing operations. However, the real value of IIoT lies not in data collection alone, but in how that data is used to improve processes, reduce costs, and drive smarter decision-making across the entire organization.

The power of IIoT can transform manufacturing operations, but to realize its full benefits, companies need to focus on how to effectively manage and utilize this data, turning it into actionable insights that improve factory efficiency, product quality, and overall business performance.

Industry Stats & Data: The Impact of IIoT

To understand the transformative power of IIoT in manufacturing, consider the following statistics, which showcase how IIoT is reshaping industries:

| Statistic | Data | Source |

|---|---|---|

| Reduction in Downtime | 10-20% decrease in unplanned downtime due to predictive maintenance | McKinsey & Company, 2023 |

| Improvement in Productivity | 10-15% increase in productivity through automation and real-time insights | Deloitte, 2023 |

| Energy Savings | 5-10% reduction in energy consumption due to IoT-based monitoring and optimization | International Energy Agency |

| Supply Chain Efficiency | 15-20% improvement in supply chain operations due to better inventory management | PwC, 2024 |

| Cost Reduction from IoT | 30-40% cost reduction through IoT-driven predictive maintenance, process optimization, etc. | Gartner, 2024 |

Key Insights from Industry Experts: How to Get IIoT Right

1. Don’t Collect Data for the Sake of Data

A common mistake businesses make when adopting IIoT is collecting data without a clear purpose. The real value of IoT lies not in amassing vast amounts of data, but in using it to solve specific problems or seize opportunities.

Before integrating IoT, businesses should ask themselves:

- What problem is the IoT solution solving?

- What data is required to address that problem?

- What frequency of data sampling is appropriate?

By answering these questions, companies can focus on collecting relevant data and avoid overwhelming their systems with unnecessary information.

2. Bridging the Gap Between OT and IT

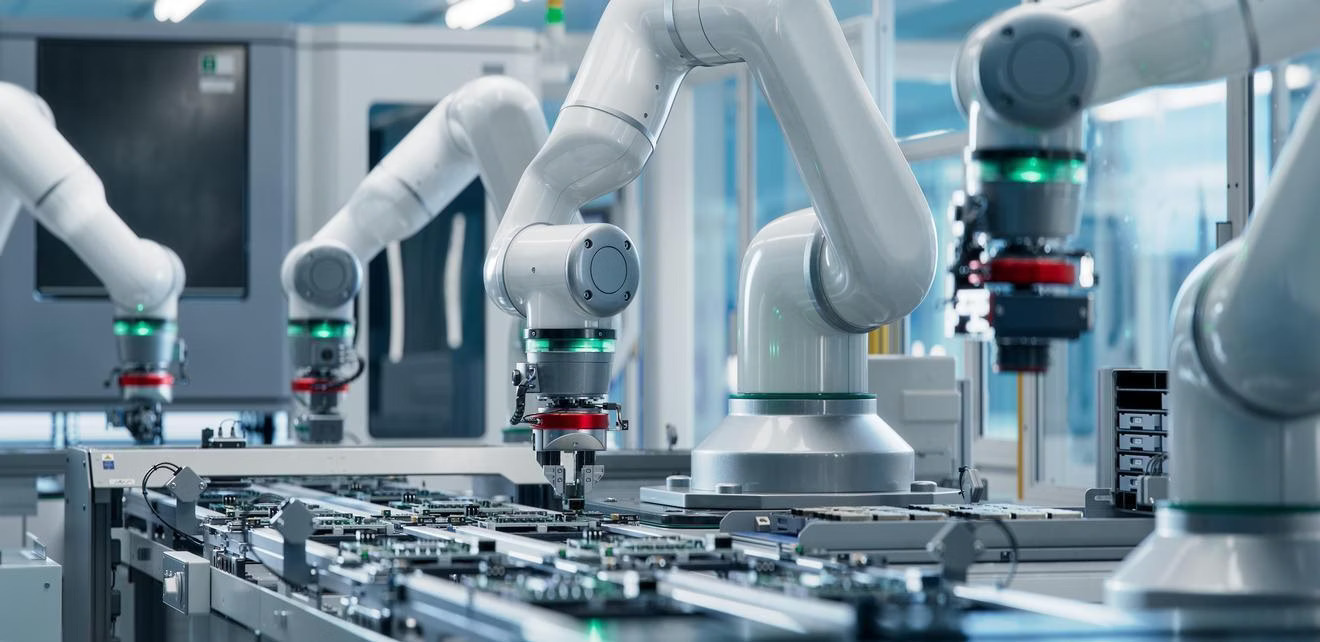

One of the most significant obstacles when implementing IIoT is integrating Operational Technology (OT) with Information Technology (IT). Factory automation, robotics, and control systems are often in place, but the true opportunity comes from connecting this operational data to business applications, extending the benefits beyond the factory floor.

By linking the data generated by machines to business applications, manufacturers can improve decision-making, streamline supply chain operations, and even enable vendors to optimize the performance of their equipment remotely.

For example, fault data from machinery can be sent directly to vendors, enabling them to optimize performance and reduce failure rates, which ultimately enhances uptime for the factory.

3. Start Small: The Power of Proof of Concept (PoC) Projects

For businesses just beginning their IIoT journey, it’s essential to start small. Rather than trying to digitize every process at once, focus on a specific challenge or process within the factory. Implement a proof of concept (PoC) with clear, measurable metrics.

This approach allows businesses to test the feasibility of IoT solutions on a smaller scale, gain valuable experience, and demonstrate the technology’s benefits to leadership. Once a PoC proves successful, it becomes easier to scale the project and implement IIoT solutions across the organization.

4. Ensuring Data Security in the Age of IoT

As manufacturing businesses increasingly rely on IIoT systems, cybersecurity becomes a significant concern. With the growing risk of cyberattacks, businesses must ensure that their IoT data is protected and securely transmitted.

Key considerations for securing IIoT data include:

- Validating Data: Ensuring that the data being transmitted is accurate and free from tampering.

- Securing Data Transmission: Using encryption and secure communication protocols to protect data as it travels through the network.

- Asset-Level Security: Ensuring that only authorized assets and systems are sending data, and protecting those systems from potential breaches.

As IIoT systems evolve and more data moves to the cloud, companies must prioritize cybersecurity and adopt a comprehensive security strategy to safeguard their data.

FAQ: Frequently Asked Questions About IIoT Systems Management

Q1. Industry 4.0 solutions and IIoT are becoming recognized for monitoring manufacturing line efficiency. What gaps do businesses miss when it comes to factory digitizing benefits?

Many businesses focus heavily on collecting data without a clear objective. Collecting data just for the sake of it does not deliver value. The real benefit of IoT lies in identifying specific problems or opportunities within the factory, larger business units, or the supply chain.

- Identifying the right problem to solve: Determine what issue or opportunity the IoT integration will address.

- Selecting appropriate data and systems: Know exactly what data needs to be captured and how frequently.

- Data sampling and analysis: Avoid overwhelming systems with unnecessary data. For example, why capture temperature data every five seconds if it’s not changing?

Q2. What are the biggest obstacles to integrating operational technology (OT) and informational technology (IT) into a full IIoT systems management program?

The integration of OT and IT is often a challenge due to the complexity of extending IoT systems from isolated equipment or production lines to the entire business infrastructure. However, these technical barriers can be solved.

One of the biggest hurdles lies in bridging the gap between the data generated by machines and its application in broader business systems. While factory automation, robotics, and control systems are already in place, the true opportunity lies in connecting the data from these systems to business applications, enhancing visibility and decision-making across the entire supply chain.

Q3. What are the low-hanging fruits for a business that hasn’t embraced the data acquisition required of an IIoT systems management program?

For businesses just starting with IIoT, it’s advisable to begin with a focused, smaller-scale project—a proof of concept (PoC). Choose a specific process or challenge within the factory and implement IoT solutions with well-defined metrics to measure success.

The key is to gain experience with a successful PoC, which will make it easier to secure management support for scaling the project across the organization.

Q4. How can a business beginning its digital transformation to a smart factory ensure its data is secure?

Security is critical as more data moves through IIoT systems and is transmitted over networks. Businesses must focus on ensuring the integrity of data, protecting it during transmission, and securing the assets that send it.

Cybersecurity should be a top priority, especially in light of increasing cyberattacks. IoT systems should use encryption, secure communication channels, and thorough asset-level protection to safeguard critical data.

Conclusion: Take the Next Step with IIoT

Implementing IIoT systems in manufacturing can transform operations, improve efficiencies, and unlock new business opportunities. However, businesses must approach IIoT strategically, focusing on solving specific challenges, integrating OT and IT systems, and securing their data.

If you’re ready to take your manufacturing operations to the next level with IIoT, contact us for a consultation and see how we can help you implement an effective IIoT systems management solution tailored to your business needs.