Introduction

The oil and gas industry is very important for energy around the world. It provides more than 61% of the world’s energy. However, this industry faces big problems like pipeline leaks and theft, which cost companies $10 billion each year in the U.S. alone. With 2.5 million miles of pipelines in the country, keeping these pipelines safe is a big challenge.

Old methods of finding leaks—like manual checks and inspections—are not effective anymore. These methods are slow, expensive, and not always successful. This is where the Internet of Things (IoT) comes in. IoT provides real-time leak detection and helps companies save money and protect the environment.

Challenges in Pipeline Monitoring and Leak Detection

Pipeline leaks cause huge problems for oil and gas companies. On average, pipelines in the U.S. have 93 leaks per mile. The main causes of these leaks are:

- Corrosion, which is responsible for 61% of the leaks.

- Other factors, like mechanical failures, make up the remaining 39%.

In the past, companies used manual methods to inspect pipelines. These inspections took a lot of time and missed small leaks that later became big problems. This is why oil and gas companies are switching to IoT for real-time monitoring and quicker solutions.

How IoT Helps Detect Pipeline Leaks

With the rise of Industry 4.0, technology like IoT is changing how industries operate. In oil and gas, IoT offers big benefits:

- Continuous monitoring: IoT sensors watch over pipelines 24/7, so leaks can be found right away.

- Remote monitoring: Pipelines in hard-to-reach areas can be checked without sending workers on-site.

- Predictive maintenance: IoT helps companies predict when repairs are needed before something breaks down.

IoT Solutions for Oil and Gas Leak Detection

Real-time Alerts and Leak Detection

Before IoT, companies checked pipelines by sending people to inspect them. This was slow, and leaks were sometimes found too late. Now, with IoT sensors, companies get real-time alerts whenever a leak happens. This means they can fix the problem right away, preventing big environmental damage and saving money.

Before IoT:

- Inspections were done every few months.

- Leaks were found too late.

- Expensive clean-ups were often needed.

After IoT:

- Continuous monitoring.

- Leaks found immediately.

- Quick action saves money and reduces damage.

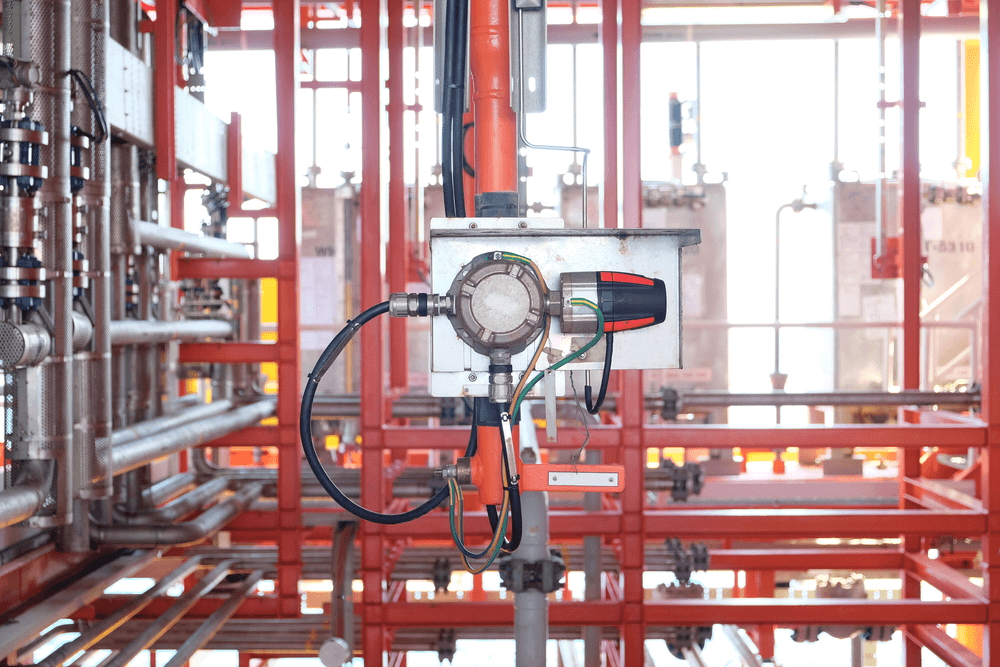

Sensors Used for Leak Detection

IoT uses many different sensors to track pipelines. Some of these are:

- Pressure, flow, and temperature sensors: These measure important pipeline conditions.

- Smart pigs: Special tools sent inside pipelines to check for cracks or corrosion.

- Infrared cameras: Used to detect gas leaks that the eye cannot see.

- Fiber optic cables: These detect temperature changes, which can show where leaks are happening.

Remote Area Monitoring

Pipelines often run through remote and hard-to-reach places. Before IoT, inspecting these areas was difficult and expensive. Now, IoT sensors monitor these areas in real time and send data directly to control rooms. If a leak is found, the system can even shut down the pipeline automatically.

Benefits of IoT in Pipeline Operations

Real-time Equipment Monitoring

Before IoT, companies only found out about equipment failures after they happened. This caused big problems and expensive repairs. With IoT, sensors monitor equipment like pumps, motors, and compressors all the time. By tracking things like pressure and temperature, companies can spot problems early and fix them before they lead to breakdowns.

Methane Gas Detection

Methane leaks are very dangerous. They can cause explosions and harm the environment. IoT sensors can detect methane leaks early, which prevents serious damage and helps companies avoid heavy fines.

For more information on how IoT can help reduce methane leaks, check out Rejig Digital’s article on IoT and emissions.

Reducing Environmental and Legal Issues

IoT also helps companies follow environmental laws by finding leaks early. This stops leaks from becoming bigger problems, which could lead to fines or lawsuits. Companies can save money and protect the environment at the same time.

Business Benefits of IoT

Lower Costs

IoT helps companies save money by finding leaks early, before they become expensive to fix. With real-time monitoring, companies no longer need to spend a lot of money on manual inspections. IoT systems automatically check pipelines for leaks, helping companies avoid expensive repairs.

Before IoT:

- High labor costs for manual inspections.

- Expensive repairs when leaks were found late.

- Huge environmental clean-up costs.

After IoT:

- Lower costs with automatic monitoring.

- Leaks found early, leading to cheaper repairs.

- Reduced environmental damage.

Increased Pipeline Uptime

IoT also improves pipeline uptime. With IoT, companies can predict when equipment will fail and fix it before it breaks down. This means fewer interruptions and more efficient operations.

Safer Workplaces

IoT helps keep workers safe by reducing the need for them to check pipelines in dangerous areas. Sensors provide early warnings about potential risks, allowing workers to handle problems from a safe distance.

Digital Transformation and ROI in Oil & Gas

IoT is a smart investment for oil and gas companies. Although setting up IoT systems can be expensive at first, the long-term savings are worth it. With IoT, companies can reduce their operational costs, improve safety, and increase uptime.

Cost to Implement IoT:

Setting up an IoT system depends on the size of the pipeline, the number of sensors needed, and the features you want. On average, the cost to implement IoT ranges from $500,000 to $2 million for mid-sized companies. But the savings from preventing leaks and avoiding environmental damage make it a good investment.

Before IoT:

- High costs for manual inspections and repairs.

- Frequent pipeline leaks.

- Lost revenue from downtime.

After IoT:

- Lower costs for monitoring.

- Leaks detected early, saving on repairs.

- Less downtime means more profit.

Conclusion

The use of IoT in the oil and gas industry is changing how companies detect leaks and monitor pipelines. From real-time data collection to early leak detection, IoT helps companies reduce costs, improve efficiency, and keep pipelines running smoothly.

As the industry continues to embrace digital transformation, Rejig Digital is leading the way by offering IoT solutions that help oil and gas companies monitor pipelines, reduce downtime, and comply with environmental regulations.

Discover Rejig Digital’s IoT solutions today and start modernizing your pipeline operations for a safer, smarter future.