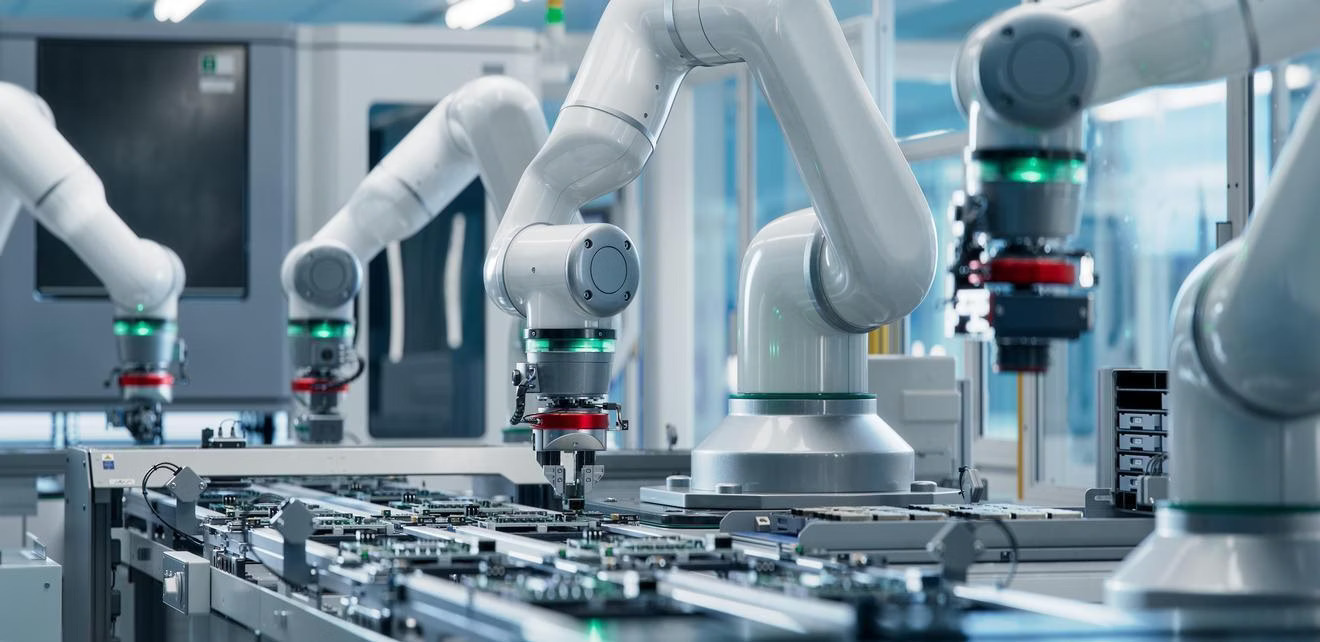

The Internet of Things (IoT) and Industry 4.0 have brought the wave of transformation for the manufacturing sector. These technological advancements have brought major changes in core business processes and paved the way for automation. Be it a supply chain, procurement, business intelligence, or human resources, industrial IoT solutions can refine every process to bring transformation. These solutions contribute to operational efficiency and workflows also.

In this article, we are going to discuss the role of IoT technology in Industry 4.0 and the manufacturing sector. But, before moving forward, let’s understand the concept of Industry 4.0.

Introduction of Industry 4.0

Interconnectivity, real-time monitoring, automation, and exchange of data are four pillars of this industrial revolution known as Industry 4.0. The concept is completely customer-centric and requires manufacturers to put all effort to deliver excellent customer experiences and services. Here, the customer-centric approach consists of product sales, manufacturing, assembling, and service management.

With the help of the Industrial Internet of Things (IIoT) concept, manufacturers can easily meet these necessities and resin updated with the ever-changing expectations of customers.

IoT and Industry 4.0- How This Combination Brings Revolution

IoT contributes to the super-fast evolution of Industry 4.0, where everything is connected using a common network with automated operations. It eliminates or minimizes human intervention. With real-time data monitoring, manufacturers can improve the decision-making process. What’s more, IoT in manufacturing companies to bring predictability for reducing the chances of any hazardous issue in the industry.

Here are the main aspects of IoT and Industry 4.0 in the manufacturing sector-

– Generating insights

– Bringing innovation

– Optimizing processes

– Connecting devices

Simply put, the IoT and Industry 4.0 combination facilitates asset management to improve future workability. The main objective of an Industrial Internet of Things (IIoT) is to make everything smart everywhere. On the other hand, Industry 4.0 consists of various emerging concepts including Augmented Reality (AR), Big Data, cloud computing, digital twin, and autonomous robots.

IoT can contribute to the concept of manufacturing excellence while playing a vital role in every industrial process. It can generate valuable outcomes while integrating into the complex industrial solution. IoT can improve these processes effectively and offer multiple benefits to the manufacturing sector.

Major Benefits of IoT Solutions for Industries

IoT technology can effectively combine IT and operations while processing in sync with advancements of emerging technologies. Some of the top benefits of IoT include

1. Predictive Maintenance

This is one of the biggest benefits of industrial IoT solutions. Implementation of IIoT solutions can help the process managers predict and respond to the asset’s workability with a predictive maintenance feature. The IoT concept ensures better performance of assets so that there will be no damage to productivity and processes.

Also Read- How Industrial IoT is Transforming the Businesses in 2022

2. More Efficiency

Customized IoT solutions can improve operational efficiency significantly by optimizing various industrial processes. It also brings automation to boost productivity and streamline the overall functioning of factories irrespective of the industrial sector. IoT technology enables manufacturers to track the asset’s performance in real-time with the help of embedded sensors.

3. Cost-reduction

With real-time data monitoring and predictive maintenance features, IoT can contribute to reducing operations costs significantly. The technology makes the equipment smart enough to perform operations without human intervention. This can reduce errors and decrease the costs associated with various projects. In a way, IoT and Industry 4.0 combination remains cost-effective for various industries.

4. Data Monitoring

Real-time data monitoring is another noteworthy benefit of IoT. Customized IoT solutions make it possible to track the performance of any assets thereby manufacturers can make the relevant changes in the process. As a result, productivity and product quality will increase substantially. What’s more, real-time data monitoring also provides actionable insights to enable companies to make meaningful decisions.

Be it manufacturing, energy, oil & gas, transportation, or any core industry sector, IoT and Industry 4.0 combination will revolutionize key processes. These days, almost every enterprise tends to implement IoT-based smart systems to make the most of technological advancements and increase productivity over the period in the coming years. IoT solutions can also work and monitor under extreme conditions, and therefore, they can offer an excellent future to enterprises.

Concluding Lines

Industry 4.0 or the fourth industrial revolution has transformed the production cycle and supply chain at manufacturing units. Industrial IoT solutions contribute to making our industries smart and enhancing workflows. It is fair to mention that IoT will drive Industry 4.0 in the year 2022 and beyond by introducing advanced approaches rapidly.

At Rejig Digital, our in-house team offers robust and customized IoT solutions for modern enterprises across different industry verticals. We integrate advancements of AR and other emerging technologies to simplify complexities and increase productivity for your company. Simply drop us a line at info@rejigdigital.com to know more about our advanced enterprise-level solutions.