Hello, and welcome! If you work in oil and gas, you are surely aware of how vital it is to keep everything flowing and functioning. Leak detection is critical to safety and operability. Whether these are pipelines, offshore platforms, or storage tanks, undetected leaks can cause significant issues. Rejig Digital is an innovative IoT-based solution provider that could help mitigate this problem by rethinking how leakage is detected in the oil and gas sector.

Leak detection has always been a challenging task for companies in this sector. Companies that rely on old-fashioned approaches often fall short, as these methods take a long time, are expensive, and the manual inspections are not reliable enough to prevent damage. This is why IoT-based leak detection solutions have been implemented. With Rejig Digital, we are improving the status quo by employing advanced sensors, cloud computing, and artificial intelligence (AI) to provide real-time, accurate, and automated leak detection.

In this blog, I am set to discuss how Rejig Digital’s IoT-based solutions function, while also informing you about their ability to help your oil and gas business stay safe, efficient, and compliant with regulations. Not only will you understand that our system is a smart investment that can save you money, time, and reduce risks, but by the end, it may even become the turning point for transforming your entire business operations.

The Challenges of Traditional Leak Detection Methods in Oil and Gas

Let’s start by looking at how leak detection is usually done in the oil and gas industry. Many companies still rely on traditional methods such as:

- Manual Inspections: This involves workers physically checking equipment, pipelines, and tanks for any signs of a leak. While this method has been in use for years, it has some serious downsides.

- Visual Checks: This involves looking for visible signs of leaks, like stains, puddles, or the smell of gas. However, not all leaks are visible to the naked eye, especially small leaks or those in hard-to-reach places.

- Scheduled Monitoring: This is when inspections are done on a set schedule, like once a month or quarterly. The problem with this method is that a lot can happen between inspections. If a leak happens right after an inspection, it could go unnoticed for weeks or even months.

These methods have some major limitations:

- Delays in Detection: Since traditional methods rely on human checks, leaks can be missed, or there might be a delay in identifying them.

- High Costs: Manual inspections are not only time-consuming but also expensive. Plus, if a leak is missed, the costs to fix it can skyrocket.

- Environmental and Safety Risks: If leaks go undetected, they can cause serious harm to the environment and put workers’ safety at risk. In the worst-case scenario, they can lead to explosions or toxic spills.

The oil and gas industry needs a better solution. You need something that can help you detect leaks faster, automatically, and accurately without relying solely on human checks. This is where Rejig Digital’s IoT solutions come in. Let’s look at how our system works to solve these problems.

How Rejig Digital’s IoT-Based Leak Detection Works

Rejig Digital uses Internet of Things (IoT) technology to improve how leaks are detected. In simple terms, IoT connects physical objects (like sensors) to the internet, allowing them to send and receive data in real-time. Our IoT-based leak detection system uses a combination of advanced sensors, cloud computing, and AI to keep track of your assets 24/7.

Here’s how it works:

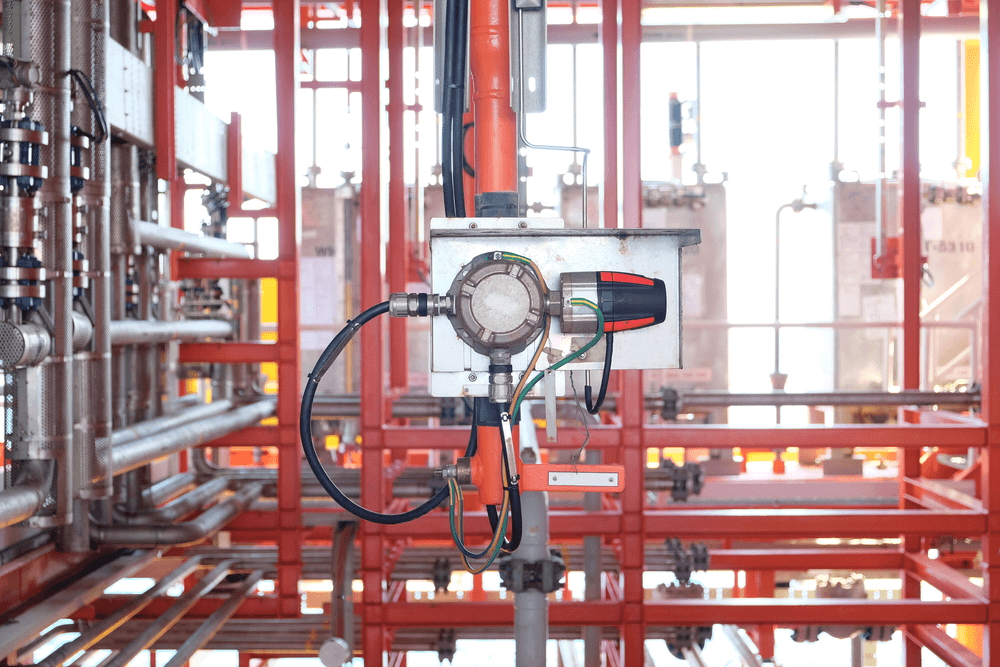

- Advanced Sensors: We install smart sensors that can detect small changes in the environment. These sensors measure things like pressure, temperature, flow, acoustic signals, and vibration. Even the slightest change could signal a potential leak. If something’s wrong, the sensor will immediately send the data to our system.

- Communication Technology: These sensors don’t work alone. They send their data to a central system using wireless communication technologies like LoRaWAN, 4G/5G, or even satellite connections. This ensures your assets can be monitored even if they are located in the middle of the ocean or in remote areas where regular internet connections aren’t available.

- Cloud-Based Platform: All the data collected by the sensors is sent to the cloud, where it’s analyzed in real-time. This means your team can access the information from anywhere. With cloud computing, the data is processed and analyzed quickly, making it possible to detect leaks much faster than traditional methods.

- Artificial Intelligence (AI) and Data Analytics: Once the data reaches the cloud, AI-powered algorithms start analyzing it. These algorithms can detect patterns in the data, recognize abnormal behavior, and predict where and when a leak might occur. If a potential leak is detected, the system will send an instant alert to your operators.

So, instead of relying on human checks and scheduled inspections, Rejig Digital’s system continuously monitors your equipment and sends instant updates when something is wrong. This means you’ll know about leaks as soon as they happen—before they can cause significant damage.

Key Components of Rejig Digital’s IoT-Based Leak Detection Solutions

Now, let’s break down the key components of Rejig Digital’s IoT-based leak detection system and how they work together:

- Advanced Leak Detection Sensors: These smart sensors detect small changes in pressure, flow, acoustic, and vibration. They are designed to pick up even the smallest leak early on, helping you avoid major issues. For example, a drop in pressure in a pipeline could indicate a small hole, and an unusual vibration could point to a malfunctioning pump.

- Data Acquisition Units (Gateways): These units collect the data from the sensors and securely transmit it to the cloud. Whether your assets are onshore, offshore, or in remote locations, these gateways ensure that the data gets to where it needs to go.

- Cloud-Based and Edge Computing Platforms: The cloud platform processes the data in real-time, enabling quick leak detection. Edge computing comes into play by analyzing data locally, on-site, which means responses to potential leaks can happen instantly without waiting for cloud-based processing.

- User-Friendly Dashboards and Mobile Apps: Our platform isn’t just about collecting data. We want to make it easy for you to act on that data. Dashboards provide a clear view of the system’s health, and mobile apps allow operators to respond to leaks and alerts from anywhere. These tools make it easy to stay on top of your operations, no matter where you are.

Benefits of Rejig Digital’s IoT-Based Leak Detection for Oil and Gas Companies

So, what are the benefits of using Rejig Digital’s IoT-based leak detection system? Here are the key advantages:

- Early Detection and Prevention: By using real-time monitoring, we can detect even the smallest leaks before they escalate into bigger problems. Early detection helps you act quickly, preventing costly repairs and environmental damage.

- Cost Savings: Traditional leak detection methods can be expensive because of manual inspections, downtime, and repairs. Our system saves money by reducing the need for manual labor and helping you fix issues before they become expensive problems.

- Enhanced Safety: Leaks, especially in offshore or remote areas, can pose serious safety risks. With early leak detection, you can reduce the chances of accidents, protect workers, and prevent explosions or toxic releases.

- Predictive Maintenance: Our system doesn’t just detect leaks—it also helps predict when equipment might fail. This means you can schedule maintenance before something breaks down, saving you from unexpected costs and downtime.

- Regulatory Compliance: The oil and gas industry is highly regulated. Our solution helps you stay compliant with safety and environmental standards by giving you the data and documentation you need for audits and reports.

Real-World Applications of Rejig Digital’s IoT-Based Leak Detection

Let’s take a look at how Rejig Digital’s IoT-based leak detection system can be used in different parts of your oil and gas operations:

Oil and Gas Pipelines: Pipelines are the lifeblood of the oil and gas industry, but they can be vulnerable to leaks. Our system monitors the pressure and flow in pipelines, detecting leaks early and allowing you to address them before they cause serious damage.

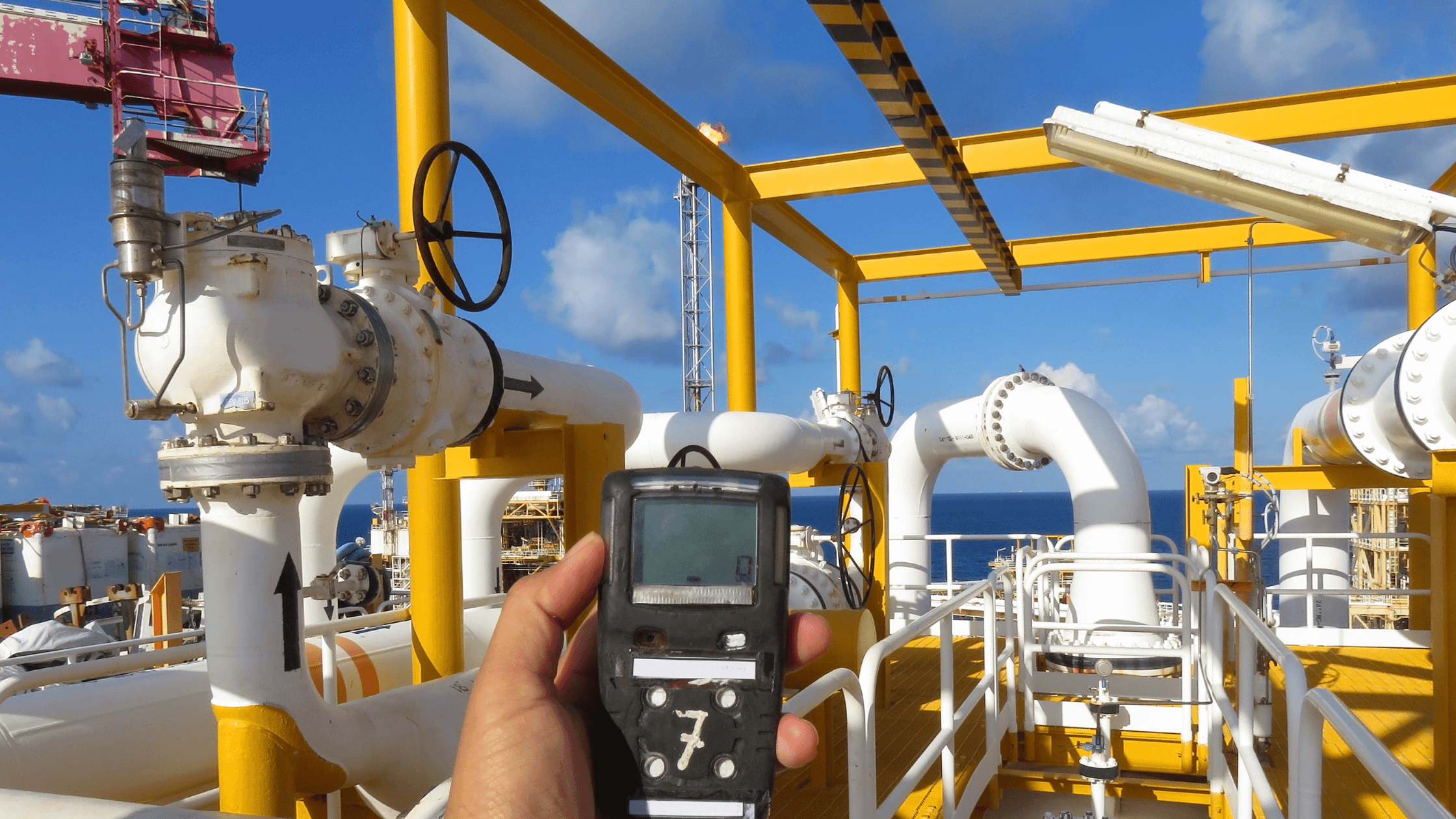

Offshore Platforms and Wellheads: Offshore platforms face harsh conditions. Our IoT-based solution monitors wellheads and offshore rigs, detecting potential leaks in real-time, even in the middle of the ocean.

Refineries and Storage Tanks: Leaks in storage tanks or refineries can lead to dangerous spills. Our system constantly monitors tanks and refineries for any signs of leakage, helping you catch leaks before they escalate.

Field Equipment and Drilling Sites: Drilling operations use heavy machinery and equipment that can wear down over time. By monitoring the pressure and flow in these systems, our solution helps detect potential issues in drilling rigs and equipment, preventing costly downtime and repairs.

Overcoming Challenges with Rejig Digital’s IoT Solutions

We understand that introducing new technology can come with its challenges. But Rejig Digital’s IoT solutions are designed to address these concerns:

- Minimizing Initial Investment: Our solutions are scalable and can be tailored to fit your business needs. You can start with a small setup and grow as your business expands, making it a cost-effective investment in the long run.

- Adaptability to Harsh Environments: The oil and gas industry often operates in remote, harsh environments. Our sensors and systems are built to withstand extreme temperatures, corrosion, and other environmental challenges.

- Data Management and Analytics: We provide real-time analytics, and our AI algorithms ensure that the data is actionable. You won’t have to sift through piles of data to figure out what’s important—we help you focus on what matters.

- Seamless Integration: Rejig Digital’s solutions are designed to integrate smoothly with your existing systems, such as SCADA, asset management, and other operational platforms. There’s no need for a complete overhaul of your systems.

Conclusion

In conclusion, Rejig Digital’s IoT-based leak detection solutions are helping oil and gas companies become more efficient, safer, and compliant. By switching to automated, real-time monitoring, you can catch leaks early, save money, and protect your people and the environment.

Want to see how Rejig Digital’s IoT-based solutions can work for your business? Schedule a demo or consultation today! Let’s discuss how our smart leak detection system can save you time, money, and reduce risks. Contact us for a personalized assessment of your needs. Together, we can improve safety, efficiency, and compliance across your operations.